The world of retail seems to have a continuous supply of growing problems. One such well-known name is reshipment. For suppliers, every reshipment request means more cost, more time, and more possible deductions.

The world of retail seems to have a continuous supply of growing problems. One such well-known name is reshipment. For suppliers, every reshipment request means more cost, more time, and more possible deductions.

iNymbus oversees how each reshipment directly affects profit margins and cash flow. We’re going to break it all down and explain in detail how automation can fix this problem.

What Do We Know About Reshipment?

Reshipment is triggered by a request from the retailer or customer for a replacement. The cause for such requests can be loss of items, damage to goods, short shipment, or late delivery.

Retailers prefer for the goods to be replaced instead of waiting for claims to be resolved. Even if it maintains customer satisfaction, the operational and financial strain it creates on suppliers is much greater.

What Causes Reshipment?

There are several reasons to request reshipments, including:

- Damage to goods during transit

- Packages lost or stolen

- Incorrect shipments – wrong item, color, size, or quantity

- Shortage detected during original delivery

- Failed attempts at delivery or issues with the address

- Misreporting caused by errors in retailer systems

What does a reshipment case require? Regular rounds of investigation, documentation, and resolution. You can expect additional deductions and penalties upon delay in managing reshipment.

The Hidden Costs of Reshipment

At first glance, many things do not appear significant. That is where we need to pay the most attention. Every reshipment can add up multiple hidden costs:

- Freight and handling charges to send replacement orders

- Packaging costs for new shipments

- Labor hours to manage reshipment paperwork and other requirements

- Inventory loss due to already replaced goods is counted as sold

- Deductions charged by retailers for compliance violations or late deliveries

Impact of Reshipment on Deduction Management

A significant number of the reshipments ultimately result in deductions later in the process. Here’s how:

- The original invoice may be deducted by the retailer because of short-shipment claims.

- Late shipment penalties or chargebacks can also trigger deductions.

- All along, the supplier is already incurring internal reshipment costs.

- It becomes chaotic to track both original and reshipped orders without automation.

- Many suppliers lose thousands in unclaimed deductions each month as a result.

From The Retailer's Perspective

Reshipments are crucial to protecting customer experience and satisfaction, from the retailer’s point of view. Retailers require faster resolution to these issues. And sometimes, this requirement pushes for reshipments before actual claim validation.

Suppliers are at a disadvantage with both the operational and financial burden shifted on them. To add to the complexities, retailer policies and portals often show inconsistencies to be dealt with.

A Common Case of Reshipment

Here’s a typical reshipment scenario:

- Walmart receives a shipment, but a 5% shortage is noted.

- They request a reshipment of the missing units.

- Expenses for reshipment are incurred by the suppliers themselves.

- Walmart deducts the value for the shortage of original items from the next invoice.

- Suppliers are tasked with proving whether the original shipment was complete or not.

- Permanent deduction is applied in case of delayed disputes or unavailable documents.

The Link Between Reshipment and Compliance Issues

Reshipments can expose certain issues like:

- Mismatch in ASN (Advanced Shipment Notices)

- Errors in labelling

- Issues in barcode scanning

- Non-compliance in packaging

- Failure in delivery with the carrier

These compliance failures don’t just result in reshipments; they often lead to additional retailer chargebacks, increasing operational costs, and damaging retailer relationships.

🔎 Read more in our latest blog post to understand how automation can help prevent these costly issues.

The Pain of Managing Reshipments Manually

Manual process to manage reshipment involves:

- Going through old invoices, POs, and shipping documents

- Communicating information to multiple departments (warehouse, logistics, finance)

- Submit dispute packets to retailer portals

- Track responses and follow-ups

- Reconcile financial statements after resolution

Manual resolution of reshipment claims can take an average of 45-90 minutes per claim. Now, if we multiply that by a hundred or thousands, the consequent impact is huge.

How Can iNymbus Solve The Reshipment Challenge?

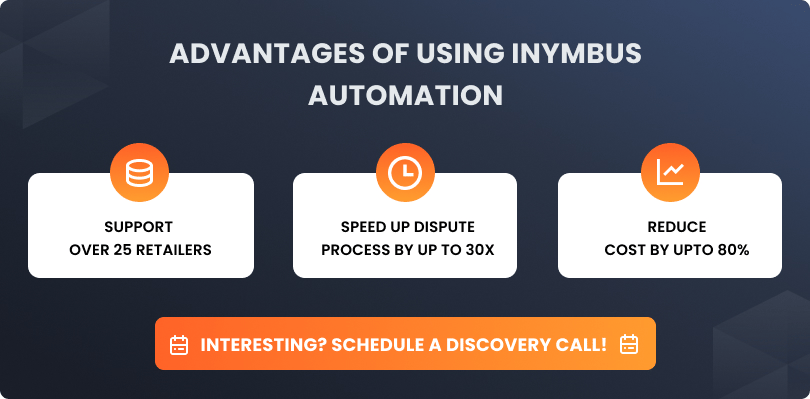

iNymbus brings in the game-changing automation to tackle this issue.

Key Features:

- Claims extracted automatically from retailer portals

- Smart retrieval of documents from ERP, carrier, and warehouse systems

- Matching invoices, shipping, and ASN data using AI

- Dispute packets are generated automatically for retailer compliance

- Tracking claim outcomes and financial recoveries in real time

Why is Automation Quintessential?

With automation, you can ensure alignment of every document, number, and date across all these stages. iNymbus can help suppliers resolve reshipment issues in minutes!

iNymbus Workflow for Reshipment Dispute Automation

Here’s how iNymbus simplifies a complex reshipment dispute:

| Step |

Without iNymbus |

With iNymbus Automation |

| Claim Notification |

Pulled manually |

Auto-pulled regularly |

| Gathering Documents |

Search across 4–5 systems |

Smart centralized fetch |

| Matching Data |

Manual spreadsheet work |

AI-driven matching |

| Filing Disputes |

Manual entry in each portal |

Auto-filed in batches |

| Follow-Up |

Calendar tracking |

Auto-reminders & alerts |

When to Automate Reshipment Management?

You should consider automation if:

- You are handling over 100 reshipment-related claims per month

- Your team is spending hours assembling disputes

- The dispute success rate is under 80%

- Unresolved claims are escalating into permanent deductions

- Finance teams are struggling to reconcile reshipment expenses

Measurable ROI for Reshipment Automation

Read the full guide on Return On Investment here.

Losses Need Not Follow Each Reshipment

Reshipments are a responsibility for the suppliers to deal with. And along with that, the financial drain that follows. However, suppliers can adapt to automation to increase recovery rates and reduce the drains and losses. What you need is a smarter team, not a bigger one.

Control of Reshipment Deductions in Your Hands

At iNymbus, we help suppliers regain control quickly and compliantly. The platform integrates seamlessly with Amazon, Walmart, Target, Costco, and over 40+ other retailers. Shift to automation today for faster and stress-free reshipment deduction management.